B - Implementation actions

B.1. Optimization processes and design parameters

B.1.1 Algae and cork preparation.

Different initial consortia of microalgal-bacterial biomass were obtained from biomass attached on the foam in the bench-scale PBR located in CSIC facilities (bench scale PBR described in Action A3; deliverable D6). “Mixed culture” and monospecific cultures “B2” and “B12” were obtained as inocula.

The mixed culture has been grown up at IRTA at different scales (50 mL, 5 L, and 200 L) under batch mode, by using real groundwater (GW) from IRTA site and supplemented with CO2 and phosphate at different dosages (N:P molar ratio of 46, 31, and 20) to boost microalgae growth.

- The most abundant living microorganisms in the mixed culture were initially green microalgae and bacteria, without the presence of fungal populations. The microalgal population in the ‘mixed culture’ was dominated by Kalenjinia gelatinosa (relative abundance RA>60%), with Micractinium pusillum also enhanced (RA =15%) and Chlorella (RA =10%), compared to starting foam biomass from CSIC, whereas Tetradesmus obliquus was greatly reduced in relative abundance (from RA =80% to RA <5%). This shift of the microalgal community in relation to the original is not surprising since the composition of the groundwater (e.g., very high in nitrates, different bacterial composition) and environmental conditions during culturing (e.g., light, temperature) differed.

- Regarding Cyanobacteria, only phylotypes belonging to family V; GpV; assigned close to Leptolyngbya were depicted at low abundance in the mixed culture (RA =0.07% of total Bacteria), which were even lower than observed in the initial biomass from CSIC (RA =1%). Regarding bacterial populations, the mixed culture revealed a clear different diversity and composition compared to the initial biomass. Most predominant phyla and families were Bacteroidetes (RA =70% vs 6% in starter) (family Chitinophagaceae), Alpha-proteobacteria (RA =15% vs 72% in starter) (families Sphingomonadaceae, Phyllobacteriaceae, and Caulobacteraceae), Acidobacteria and Parcubacteria.

- Studies were done to assess the occurrence of cyanotoxins in the resulting water by using fast-test (immune-enzymatic assays) compared to confirmative analytical methods (LC-MS/MS).

Monospecific microalgal cultures B2 and B12 were also isolated from initial starter biomass to provide microalgal culture inoculum free of cyanobacteria. Both cultures contained only one microalga species: Tetradesmus obliquus and did not contain cyanobacteria (confirmed by 16S-high throughput sequencing) but did contain mixed bacterial populations belonging mainly to alpha-, and beta-proteobacteria and Bacteroidetes phyla encompassing different families between them (B2 culture compared with B12). Culture B2-B12 has de capacity to growth in Nules water showing a moderate removal capacity of nitrates where an optimization of N:P dosage is also needed.

Operation of 200 L photobioreactors (PBR) equipped with light-pits and inoculated with the mixed culture: it was installed at IRTA and NENUPHAR facilities, inoculated with mixed culture, were operated under batch and continuous mode to assess the effectiveness of the mixing system and nitrate removal. At IRTA, the groundwater of this site was used containing 450-700 mg-NO3-/L and 10-50 ng-Antibiotics/L; at NENUPHAR facilities, the groundwater was spiked with nitrate up to 250 mg NO3-/L. All reactors were started with the mixed inoculum produced at IRTA, which contained 0.2-0.5 g/L of biomass.

Different key design parameters were being assessed: CO2 and phosphorus dose (Nitrate: Phosphate molar ratio of 46, 30, 22), as well as the hydraulic residence time (HRT; 8, 4 and 2 days). The results indicate that,

- Under continuous operational mode (IRTA), PBRs were able to achieve a minimum removal of 6% and a maximum removal of 29 % initial-nitrate, similarly than observed in monospecific B2-B12 cultures or mixed inoculum production. The best nitrate removal was observed in continuous with HRT of 8 days and a nitrate to phosphate molar ratio of 46, followed by HRT of 4 days and ratio of 30. Also, under continuous operation with a HRT of 4 day, the best nitrate removal capacity was attained (4.3-5.6 g N-NO3-/m3PBR·d).

- Regarding the antibiotic reduction (sulfacetamide, sulfamethazine, and enrofloxacin) in the mixed culture-PBR (200L) operated at IRTA under HRT of 8 days, was about 33 % but decreased to 20 % at HRT of 4 days in all 3 microcontaminants (concentration range between 10 and 50 ng/L). Therefore, to maintain a proper performance both in nitrate and antibiotic removal in continuous PBRs, a HRT of 8 days is suggested.

- Under batch operational mode (NENUPHAR), PBRs photobioreactors with water from Perpignan showed a greater removal of 80 % initial-nitrate after 4 days, although removal capacity decrease in subsequential cultures throughout time. The main difference was the contained biomass: whereas in PBRs at IRTA had a suspended biomass (TSS) <0.2 g/L, in Nenuphar reactors it was of 0.5 g/L. Nevertheless, the TSS content was improved to 0.190 g TSS/L when PBRs were run under continuous operational mode with HRT of 4 days and nitrate to phosphate molar ratio of 30. Accounting the carbon contained per mass of TSS (0.5 g/L), the sequestered carbon under this operational condition is estimated in 0.38 g-C seq /L-treated groundwater.

- Microbial community assessment in continuous PBRs (IRTA) revealed that total microbial populations and denitrifying bacteria were decreased in planktonic biomass when HRT was decreased gradually from 8 days to 2 days, probably due to washing events under low cell growing rate. However, total bacteria and denitrifying bacteria were maintained in the biofilms, confirming the importance of biofilms on light-pits and wall of PBR to immobilize biomass (microalgae and bacteria) if low HRT were applied. Also, the “mixed culture” lost the nitrate removal capability at long term in Perpignan’s water, possibly due to blooms of cyanobacteria in the biofilms (also observed in IRTA’s groundwater PBR) at high nitrate and phosphate concentration.

The final microalgae inoculum of mixed culture will be used to seed the pilot plants at Caldes de Montbui (3x 200 L of inoculum) and Perpignan sites (10-20 L of inoculum) (actions B3 and B4). Considering potential blooms of cyanobacteria in the biofilms, the cultures B2-B12 will be also used in Perpignan site pilot as inoculum as a contingency plan. In case of no cyanotoxins occurrence in the mixed culture, the culture could be also used in Nules site due to its good potential to growth (N: P molar ratio of 30) achieving a nitrate removal of 27% in 9 days. In case of using B2 and B12 inoculum in Nules, then N:P should be optimized to enhance growth of microalgae.

A summary of nitrate removal capacity and biomass generation in TSS of different cultures growing in different water sources are described below (Table 2)

|

Culture (8 days) |

Groundwater |

Initial NO3 (mg/L) |

NO3 removal (%) (8 days) |

Initial TSS (g/L) |

Final TSS(g/L) (8 days) |

|

Mixed Culture |

Caldes de Montbui |

800-400 |

15-20% |

<0.05 |

0.2-0.3 |

|

Nules |

133 ±3.5 |

27% |

<0.05 |

0.2 |

|

|

Perpignan |

250--700 |

80-20% --5% |

<0.05 |

0.4-0.5 |

|

|

B2+B12 |

Nules |

133 ±3.5 |

9% |

<0.05 |

0.14 ±0.01 |

|

Caldes de Montbui |

651 ±59 |

17% |

<0.05 |

0.35 ±0.01 |

|

|

Perpignan |

250 |

ND |

<0.05 |

ND |

B.1.2 Characterization and preparation of cork waste for implementation in pilot units (PROTECMED, EURECAT).

The activities related to this action could be grouped within 3 objectives:

-

-

- Selection of the cork cleaning solution to limit the DOC concentration in the effluent (potable water).

- Determination of nitrate and other pollutants adsorption capacity.

- Determination of the best configuration of cork filters.

-

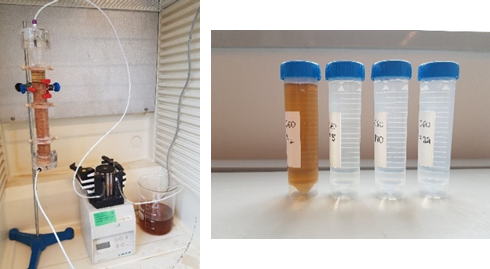

To determine the best cleaning protocol, different conditions were tested in EURECAT according to the literature (water, hot water, ethanol, acetone, NaOH). The best effluent quality was obtained after cleaning with water. Column experiments showed that all DOC was leached after 4 bed volumes, being this the proposed protocol for cleaning the filter at the beginning of the operation (Fig. 3).

Figure 3. Column to assess the cleaning protocol (left) and effluent at different time (right).

Sorption studies showed that the studied cork has no significant adsorption capacity for nitrate. On the other hand, adsorption of pesticides presented in the water from Nules (FACSA) reached >98% removal at the higher cork/water relation (10 g/L of cork) and values near 100% for bentazone in all concentrations (down to 0.01 g/L of cork) (Fig. 4). Desorption for those two pesticides was below 20%. Batch experiments have been performed in EURECAT and pesticide analysis by CSIC.

Then, column experiments were performed to assess some operational values and optimize the filtering conditions (Fig. 5). In detail, cork, obtained from the Institut Català del Suro, was characterized by EURECAT, including its filtration rate: 4.13 m/h. However, different problems were encountered, mainly:

-

-

- Problems of cork flotation that make it difficult to operate the filter.

- DOC leaching when working under intermittent operation.

-

In parallel and taking into consideration the low performance of cork in the attenuation of nitrate in A3, CSIC conducted studies to assess the effectiveness of other materials such as wood pellet (Fig. 5b). Cork and wood pellet columns were operated in continuous feeding mode in either saturated or unsaturated water conditions (HRT of 8 days) for over a year and the attenuation of nitrate and pesticides from groundwater was monitored. The results indicated that whereas the attenuation of nitrate was between 10-20% in the cork columns, the wood pellet columns achieved greater removal, being of up to 99% under water saturated conditions. Pesticides were removed up to 80% on average.

More trials to assess the function of the combination of cork and wood pellet as a biofilter using real groundwater from IRTA site were done.

B.1.3 Optimization of algae separation system from sludge (EURECAT, PROTECMED).

Separation of microalgae biomass is one of the main challenges for full-scale implementation due to the low concentration of suspended microalgae usually achieved in photobioreactors (5 g/L) or even less in the open algal ponds (0.5 g/L) and their poor settling properties.

In the SPOT treatment chain, after the microalgae reactor, a dissolved air flotation (DAF) system was placed with the aim of removing the algal biomass. DAF was selected among the current available biomass separation processes because it has been repeatedly selected among the best technologies to separate microalgae biomass and already validated at large scale. In fact, DAF has been largely used in drinking water treatment.

The optimal parameters for DAF operation (air to solids ratio, recirculation ratio, working pressure, concentration of coagulant and pH) were selected in a laboratory test screening performed in EURECAT (Fig. 6). To test the best procedure for microalgae separation, microalgae culture from laboratory experiments at IRTA was used.

The first conclusion was the necessary addition of coagulant, as no separation of microalgae was observed in DAF experiments without coagulant. Therefore, the first step has been to select the coagulant to use among those accepted for potabilization processes (Table of Annex I from the “Orden SAS/1915/2009, July 8th, sobre sustancias para el tratamiento del agua destinada a la producción de agua de consumo humano”). Due to its widespread use in drinking water treatment plants in Spain, and according to technical and economic a priori properties, the selected compound was polydiallyldimethylammonium chloride (polyDADMAC). Aluminium sulphate was selected as reference and control coagulant for laboratory tests.

Figure 6. Effluent of microalgae culture after DAF treatment with PolyDADMAC.

Therefore, jar test trials with selected coagulants were performed in order to obtain the optimal dose. Once optimized the coagulant dose, DAF assays were performed in the best conditions:

- Aluminium sulphate: pH adjusted to 5, 50 mg/L of coagulant.

- PolyDADMAC: pH of the culture without modification, 16 mg/L of coagulant.

The conclusions obtained from this activity has allowed to define important issues like:

- Chemical reagents dosage tanks and pumps

- Flocculator labyrinth

- DAF recirculation pump power and flow

- Boiler volume

- Intermediate tanks volume

Therefore, the basic design parameters for the pilot DAF system calculated by PROTECMED according to the laboratory tests was the following:

- Flow: 2 m3/h

- Recirculation pump flow: 0 - 1 m3/h

- Recirculation pump power: 0,75 kW

- Boiler volume: 100 l

B.2. Design and construction of pilot plants

An experimental platform in NENUPHAR site was installed to complete and scale up IRTA tests in order to design the pilot plants in terms of heating, aeration, CO2 injection, artificial light, floating light pits circulation.

Several tests were realized:

- Biofilm impact on the reactors according to the material used to build the light pits: PEBD or PVC.

- Nitrate removal regarding initial nitrate concentration of the water: a nitrate removal of 80% was observed in one week with an initial nitrate concentration of 250 mg/L.

- Floating light-pits circulation in the reactor. A CFD study was made to determine the light pits distribution during the scale-up of the basin.

- Impact of air bubbling and CO2 injection on the culture on the pH and the microalgae growth.

- The light spectrum and photosynthetic radiation (PhAR) were measured to optimize the microalgae photosynthesis and growth.

A Piping and Instrumentation Diagram (PID) of the pilot was drawn by NENUPHAR, with a more detailed one for the filtration unit by PROTECMED (Fig. 7 and 8). Nenuphar realized drafts of the lay-out of the three pilot plant sites.

Figure 8. 3D pictures of the filtration unit were created by PROTECMED.

B.3. Start up, operation and optimization of pilot plant at IRTA facilities

The main objective of this action is to demonstrate the capability of the SPOT pilot plant installed in IRTA Torre Marimon in Caldes de Montbui (Barcelona, Spain) to produce water of sufficient quality for livestock drinking purposes, using groundwater contaminated with high nitrate levels (300 mg/L) originating from livestock activities. Figure 1 illustrates the process sequence in the graphical abstract (Figure 9).

The results demonstrated the potential of using microalgae, and wood and cork pellets to treat contaminated groundwater.

Temperature and nitrate loading were the primary factors affecting overall system efficiency. During the first period (132-642 days), the whole system treated groundwater (1-2 m3/day) contaminated with high nitrate levels (325-162 g NO3-/L) and microcontaminants. The PHB worked at a hydraulic retention time (HRT) of 9 and 15 days, without and with recirculation of concentrated biomass, respectively. The BF operated with an HRT of 3 days and turned out to be the operational unit with the highest nitrate removal capacity (71 gNO3/m3·d), compared to the PHB (1-4 gNO3-/m3·d). The global system presented a maximum nitrate removal capacity in autumn and minimum in winter, 74 and 14 gNO3/m3·d, respectively.

In a second period (643-779 days), the BF operated alone to assess its nitrate removal capacity directly treating the groundwater. In this stage, a stepwise increment of the HRT was applied, finding that a 66 and 17 % nitrate removal efficiency was attained with HRT of 2 and 1 days, respectively. The best nitrate removal (91 % of inlet nitrate) and removal capacity (74 gNO3-/m3·d) were achieved in summer, with the PBR and BF operating at HRT of 15 and 3 days, respectively.

B.4. Start up, operation and optimization of pilot plant in a small village in Castellon (FACSA facilities)

Installation, start-up and operation of the LIFE SPOT pilot plant at FACSA facilities in Nules treating real groundwater polluted with nitrates and pesticides.

Action B4.1: Implementation of the pilot plant in FACSA facilities

LIFE SPOT pilot plant container (DAF, biofilter, pumps and vessels) was transported from Perpignan to Nules site (FACSA facilities), while the new proposed PBR with a Raceway (RW) configuration was supplied, transported and adapted by FACSA to be used in the same site. Whole pilot installation and integration Raceway-DAF-Biofilter was perfomed by FACSA including plant location, conections from water well and between stages, electric works, probes and automatic control installation and programming,

|

|

|

|

|

|

Transport and location of the pilot plant |

Installation and hydraulic tests |

Electric and automation installation and tests |

Piping and connections for process integration |

Finally, hydraulic, mechanical, electrical and authomation tests were perfomed to ensure the proper whole plant operation.

Action B4.2: Operation of the pilot plant with groundwater at FACSA facilities

LIFE SPOT pilot plant was operated from April 2023 to June 2024 in Nules treating real groundwater polluted with nitrates and pesticides. Then it was possible to validate the process performance and stability during more than one year, obtaining representative results of the operation in real conditions under different environmental conditions (all seasons).

|

|

|

|

|

|

RW operation for microalgal bioremediation |

Inoculum tank for start-up and reinoculations |

DAF system used for microalgae harvesting |

Biofilter used as final denitrification step |

RW inoculum was supplied by IRTA and grown in the Inoculum tank at Nules. After RW inoculation RW was operated in continuous mode feed with real groundwater while progressively decreasing HRT from 16 d to 8 d and supplying P and CO2 to ensure optimum microalgae growth conditions. Regular microbiological inspection in microscope and physic-chemical analyses were performed in FACSA labs during the whole operation, to control and asses process performance and stability. Microalgae harvesting after the RW was performed using the DAF during the first months of operation, but alternative S-L separation by natural settling was also studied. Microalgae thickened samples were collected and sent to IRTA for biomethanation and P recovery tests, while samples of each stage effluent were sent seasonally to IDAEA to micropollutant analyses. Biofilter (BF) was feed with the clarified water from the DAF (or settling) stage, mixed with fresh groundwater (partial bypass) since it resulted to be an effective strategy to achieve the design water treatment capacity of 1 m3/d. After a final chlorination step, it was confirmed that the LIFE SPOT process was capable to produce drinking water quality (Fig. 10 and 11).

|

|

|

|

Figure 10. Evolution of TSS and VSS in RW during operation in Nules |

Figure 11. NO3 in influent, RW effluent and BF effluent during operation in Nules |

B.5. Start up, operation and optimization of pilot plant in France.

The pilot of this action was installed in an experimental platform based in the Water Treatment Plant of Perpignan and exploited by the society VEOLIA). The objective was to reduce the nitrate and micropollutants content of 1 m3 per day of water.

The implementation of the equipment and the installation were done between January to March 2022. The pilot started to operate in April 2022. The air and water temperature, nitrate contents, pH and radiation were monitored. The pilot operated till October because of the liquidation of NENUPHAR

The results of the cultures: concentrations, productivity, nitrate removal, phosphate evolution are showed in D16.

Figure 22: View of the French pilot plant in Perpignan

B.6. Microalgae sludge valorization (All partners)

The main objective of this action B6 was to evaluate the valorisation of microalgae (MA) sludge, produced in the photobioreactor and separated in the DAF. The secondary objectives were (i) recovery of phosphorous (P) from the wasted MA sludge, (ii) feasibility to produce biogas, (iii) organic fertilizer/compost or (iv) feed supplement for livestock feeding from MA sludge.

This report is divided into two sections:

- Analysis of MA sludge from the pilot plants (task B.6.1).

- Recovery of phosphorous and sludge valorisation (proof-of-concept assay) (task B.6.2).

B.6.1. Analysis of MA sludge from the pilot plants

Regardless of the MA separation system, the produced MA sludges of the SPOT process had a dry matter or total solids (TS) content of 3-6 %w/w. The ash content was almost doubled in the MA sludge produced by flotation with the addition of chemicals (MA-B) compared to MA-A or MA-NU (concentrated without chemicals).

Therefore, the use of FeCl3 and the storage conditions of the thickened algal biomass are decisive for its correct subsequent valorisation. As conclusion, low thermal treatments did not enhance the solubilisation of TP.

The total phosphorous content comprises organic and inorganic P-compounds and ranged from 1.6 %TS in MA-NU to 3.4 %TS in MA-A or MA-B. Within the ash or inorganic content, the concentration of water-soluble phosphate (WSP) has been quantified in 41 %TP in MA-NU to 1.3-5.1 %TP in MA-A or MA-B. The total nitrogen (TN) and carbon (TC) content is another important parameter regarding microbial biodegradation. MA samples had a TN 2.8-5.0 %TS and TC of 25-43 %TS, giving a C/N ratio 25-43.

The organic matter content, measured as volatile solids (VS), varies between 38-62 %TS. If this content is quantified as chemical oxygen demand (COD), the value varies between 21-41 gO2/kg.

The MA sludges collected without chemicals addition (MA-A and MA-NU) were more biodegradable than those separated with coagulants (MA-B). However, the biodegradability values were lower than 50% COD, with values 16-40 %COD. Among this, the results pointed out that MA sludge from SPOT process is a slowly biodegradable substrate, or it contains different COD fractions whose biodegradation speed, under anaerobic conditions, is different. The methane yield obtained after 21 days were coherent with referenced values for microalgae species: 114, 153 and 57 NLCH4/kg VS for MA-NU, MA-A and MA-B, respectively.

Regarding the amino acids (AA) content, no free AA were found, but there were some identified AAs in complex form (usually peptides). The total identified AA is equivalent to 0.40-0.53 %TS. The identified AA in a higher quantity were aspartic and glutamic acid, followed by serine, glycine, alanine, and proline. MA sludges from the SPOT process could provide the main essential AAs, except arginine.

B.6.2. Recovery of phosphorous and sludge valorisation (proof-of-concept assay)

In parallel with the execution of Task B.6.1, a lab-scale system to assess the feasibility of P recovery and methanisation of MA sludge (proof-of-concept assay) was installed and operated.

IRTA implemented a lab-scale anaerobic digestion system at Caldes de Montbui, Barcelona (IRTA facilities), adapting current lab-scale equipments. This system consisted of a two-step anaerobic digester (R2), including two stirred tank reactors of 2 and 6 L for the first and second steps respectively. The first reactor run at thermophilic temperature, while the second one will operate at 35ºC. The conventional system R1 was a mesophilic stirred reactor in 1 step.

As conclusion from this task, the proof-of-concept of the biogas and digestate production using MA sludge, in the worst case (using MA-B), was demonstrated. Two anaerobic systems were tested, a conventional R1 and a 2-step system R2, finding that both systems attained similar yields (96 and 84 NLCH4/kg COD) (action B.6.2.), comparable with the potential determined by the BMP test (action B6.1). Nevertheless, the methane productivity in the 2-step AD system was slightly higher (0.17 Nm3CH4/m3·d), together with a better release of phosphorous (25.4 %TP-in).

After compiling the MA generation and characteristics, as well as the results of the test in the 2-stage anaerobic digestion system, 1.76 kg of MA-B is generated in the SPOT process per 1 m3 of groundwater GW. The MA-B biomass has a TS content of 3.8 %. Although the biodegradability under anaerobic conditions is relatively low, bio-methanization in the 2-stage system allows to solubilize sufficient total phosphorus. It has been estimated that the minimum daily P demand in the photobioreactor (based on the consumption in the Caldes de Montbui pilot that was higher than in Nules site) is 3 gP/d (deliverable D17). Considering the 25 %TP-in solubilization obtained in R2M (period P3), the minimum P demand of the photobioreactor would be covered by 77% of the digestate from the 2-stage AD system.

To assess the quality of fresh and digested MA sludges, a Rottegrade or serf-heating test was done. As main conclusion of this test, fresh MA samples are compostable if mixed with structuring agents (here the biofilter filler has been proposed) with other materials that allow the adjustment of the C/N ratio. Digested MA biomass is not compostable, at least in the mixture evaluated in this study.

Finally, in parallel with the proof-of-concept, a selected thermal and chemical pre-treatments were studied to improve the recovery of water-soluble phosphorus (WSP) from MA-B and MA-A. Only with acid addition, even at ambient temperatures, was capable to improve a 100% the WSP content in the clarified fraction of the treated MA. The disadvantage of these pre-treatments is that the biomethanization potential decreases in most cases.

One of the products obtained during the thermal pre-treatment was a hydrolysate of MA (AH), with agronomic interest given its hormone-like compound profile, that was evaluated as fertiliser in a greenhouse pot cultivation trial (proof-of-concept). As conclusion, there were no significant differences between the mineral treatment and the hydrolysate AH, that can be used as a fertilizer.

B.7. Assessment of the effectiveness of the pilot plant (IRTA, all)

The main objective of this action is to monitor the effectiveness of the pilot plants SPOT installed in two different locations: i) Caldes de Montbui (Barcelona, Spain) and ii) Nules (Castelló, Spain).

B7.1: Monitoring the removal of nutrients and micropollutants

Monitoring actions in the Pilot from Caldes de Montbui (Barcelona, Spain)

To monitor the pilot plant's performance in Caldes de Montbui, periodic samples were taken weekly or bi-weekly to measure standard water parameters (pH, conductivity, COD, SO4, NH4, PO4, NO3, NO2). Seasonal samples (Summer 2022–Summer 2023) in Periods 1 and 2 and varying flow rates (1, 2, 4 m³/day) in Period 3 were analyzed in triplicate for micropollutants (pesticides, antibiotics) and microbial diversity (16S/ITS/18S-metabarcoding). Real-time PCR assessed antibiotic resistance genes (ARGs) and microbial abundance in original and treated water, as well as in pilot units and bead material. In Spring 2023, an in-depth analysis of treated and groundwater confirmed drinking standards, and phosphorous recovery and biomethanation potential tests were conducted on flocculated microalgal biomass from the DAF process for valorization.

Evolution of the main water parameters during periods 1 and 2 in the pilot at Caldes de Montbui (see DL17):

During Periods 1 and 2, the pilot treated groundwater (1–2 m³/day) with high nitrate levels (325–162 mg NO₃⁻/L) and microcontaminants (antibiotics and pesticides from a few ng/L to 150 ng/L). Sulphates and chloride remained at 100–150 mg/L, while phosphates stayed below 1 mg/L in all seasons. pH was neutral (7–7.5), and COD in the outflow was 0–10 mg O₂/L. Nitrite levels varied with nitrate loads, and water temperature ranged from 5–25ºC, impacting nitrate removal rates in winter (below 10ºC), as microbial activity dropped. The PHB operated at 9–15-day HRT, while the biofilter (BF) had a 2–3-day HRT and achieved the highest nitrate removal (71 g NO₃⁻/m³·d), outperforming the PHB (1–4 g NO₃⁻/m³·d). Nitrate removal was better in warmer months, showing a temperature-linked denitrification pattern. The system’s nitrate removal peaked in autumn (74 g NO₃⁻/m³·d) and was lowest in winter (14 g NO₃⁻/m³·d) (see DL17). In cases where nitrate was nearly depleted (<5 mg/L), minor sulphate reduction (10%) occurred in the BF. To prevent H₂S and NO₂ buildup, an air compressor was installed in winter 2022 to maintain aerobic conditions, and COD remained within potable water limits throughout.

Screening of drinking water standards for the treated water in periods 1 and 2: To confirm the achievement of drinking standards in the treated water, two end-of-treatment (after chlorination) samplings were carried out in November 2022 and March 2023, assessing a complete list of physicochemical drinking water threshold parameters. Eight parameters out of 149 did not fit the drinking standards. COD and nitrate were slightly above the threshold due to high N load from GW, whereas the other parameters (6) were related to the low free chlorine concentration in the tank water, that was further improved. COD and nitrate fitted the drinking standards since April 2023. The demo test of water consumption by rabbits in the rabbit farm was postponed until April-May 2023, when safe NO3 and COD values were achieved (<10 mg/L and <5mg/L respectively), while free chlorine was stabilized and corrected in the tanks of treated water manually during the drinking experiment in the farm to fit the thresholds values (0.1-1 mg/L free chlorine).

Evolution of Microcontaminants, ARGs and cyanotoxins in periods 1 and 2: Groundwater had antibiotics (sulfonamides and fluoroquinolones) and pesticides (triazines) at concentrations ranging from a few ng/L to 150 ng/L. From the eleven target genes tested, only the gene targets sul1, tetM and the class 1 integron-integrase gene (intl1) were detected in the groundwater. The microalgae-biofilter treatment system effectively removed over 90% of ABs and pesticides year-round. Among the components of the treatment system, the microalgal system was the most effective at removing ABs and pesticides. However, the cork-wood biofilter (BF) showed superior performance in reducing the bacterial load in groundwater, achieving more than a 1-log reduction in the absolute abundance of genes such as sul1 and intl1. The accumulation of ABs and pesticides in microalgae biomass was minimal or undetectable (<20 ng/g of fresh weight). Overall, our results indicate that the microalgae-biofilter treatment plant is a proper solution to significantly reduce antibiotics and pesticides from groundwaters, while also producing a valuable byproduct: biomass. However, the effectiveness of the plant in reducing the load of ARGs warrants further investigation to achieve a more comprehensive understanding.

Monitoring of cyanotoxins in periods 1 and 2: In order to monitor the occurrence of cyanotoxins, water and biofilm samples were analyzed with a colorimetric competitive magnetic bead-based immunoassay, specifically developed and optimized for this project, in each year season (Spring 2022-Spring 2023). The results obtained in the screening indicated that none of the samples contained cyanotoxins (microcystins), the limits of detection being 1 μg/L of MC-LR equivalents for water samples (WHO guidance value) and 2 μg/g of MC-LR equivalents for biofilm samples.

Operation of the Pilot and evolution of the main water parameters in Period 3: The biofilter (BF) treated groundwater without prior operation of a photobioreactor or DAF units, focusing on nitrate removal under varying flows. Seasonal fluctuations were noted, with flow rates of 1.12 (HRT of 3 days), 2.53 (HRT of 2 days), and 3.32 (HRT of 1 day) m³/day recorded in July, September, and November 2023. A stepwise decrease in hydraulic retention time (HRT) led to nitrate removal efficiencies of 66% and 17% at HRTs of 2 and 1 day, respectively. The highest nitrate removal rate (91% at the inlet) and capacity (74 g NO₃⁻/m³·d) were achieved in summer with the BF operating at an HRT of 3 days.

Monitoring of microcontaminants in period 3 in the pilot at Caldes de Montbui: An increase in water flow primarily affected pesticide removal but had little impact on antibiotics. The biofilter alone achieved an average reduction of 25% to 80% for both antibiotics and pesticides. However, combining microalgae with biofilters proved more effective, even though the biofilter demonstrated efficacy on its own. In contrast, the removal of detected ARGs, sul1 and qnrS, was highly dependent on water flow, with reduced performance at higher loading rates. Overall, effective removal of micropollutants and ARGs is recommended at a lower loads.

Monitoring actions in the Pilot from Nules (Castelló, Spain)

Sampling and monitoring events in Nules: To assess the pilot plant's operation, periodic samples were collected weekly or bi-weekly to evaluate standard physicochemical parameters (pH, electric conductivity, COD, SO₄, NH₄, PO₄, NO₃, and NO₂). Seasonal sampling occurred from July 2023 to April 2024: Summer (July 12-25), Autumn (November 30-December 10), Winter (February 7-20), and Spring (April 4-23). These samples were taken in triplicate to analyze micropollutants (pesticides, antibiotics, ARGs) and monitor microbial abundance (qPCR) and diversity (16S/ITS/18S-metabarcoding) in both original and treated water, as well as in various pilot units and biofilter bead material. In Spring 2023, a comprehensive physicochemical analysis was performed on groundwater and treated water to confirm compliance with drinking standards. Additionally, phosphorus recovery assays and biomethanation potential (BMP) tests were conducted on the microalgal biomass for valorization assessment.

Operation summary and main water parameters in the pilot plant at Nules: Groundwater had a consistent nitrate concentration of 95-105 mg/L but significant pesticide presence. A High-Rate Algal Pond (HRAP) with a flexible volume of 2.2-3.3 m³ was validated over 250 days to assess its performance throughout the seasons. The effects of hydraulic retention times (HRT) from 4 to 16 days on microalgae concentration and nitrate assimilation in the PBR were studied. After the HRAP, microalgae were harvested by settling without coagulants and DAF. Initially, the HRAP achieved over 97% nitrate recovery, meeting drinking water standards (<50 mg/L). However, after day 60, the microbial community evolved, causing performance to drop to 20-60%, necessitating constructed wetlands (CWF) for further treatment to meet effluent standards.

Achievement of drinking standards in the pilot plant at Nules: in the treated water, one end-of-treatment (after chlorination) samplings was carried out in in May 2024, assessing a complete list of physicochemical drinking water threshold parameters. Four parameters out of 149 did not fit the drinking standards. Free chlorine should be increased, while no other microbiological index exceeded their thresholds. A pre- or post-treatment to reduce sulphate is needed in order to achieve drinkable water thresholds in Nules.

Seasonal monitoring of microcontaminants, and cyanotoxins in the Pilot plan at Nules: Groundwater analysis from the Nules site showed that bromacil exceeded the EU limit of 100 ng/L, while other pesticides were detected below 50 ng/L. Life Spot technology effectively removed most pesticides, including bromacil, with removal rates of 52% to 85%. However, atrazine and alachlor had lower removal efficiencies (<50%), suggesting the need for additional treatment. Overall, pesticide concentrations in the treated water remained below regulatory limits, ensuring compliance with EU drinking water standards. In addition the screening with the colorimetric competitive magnetic bead-based immunoassay indicated that none of the samples contained cyanotoxins (microcystins).

B7.4: Monitoring of microbial populations in the pilots and groundwater

Evolution of microbial populations in Period 1 and 2 in Caldes de Montbui Pilot plant:

To track microbial diversity over time (4 seasons) and identify key microbial players in the pilot’s processes, Prokaryotic, Protist, and Fungal populations were analyzed across the pilot units (PHB, DAF biomass, BF bead material). Bacterial, Archaeal, Fungal, and denitrifier abundances, along with microbial diversity (including Protists in microalgae), were assessed via (RT)qPCR and 16S rRNA, 18S rRNA/ITS metabarcoding.

Groundwater mainly contained Bacteroidetes, Proteobacteria, and ammonium-oxidizing archaea, with no predominant pathogens. In the PHB, total biomass (primarily Cyanobacteria and Protists) ranged from 100–200 mg/L of TSS.

Potential pathogenic genera in the pilot at Caldes de Montbui linked to fecal contamination (Escherichia, Bacteroides, Staphylococcus, Streptococcus) were initially present in groundwater (0.1–0.2%) but were almost fully removed (95–100%) in treated water after PBR, DAF, and BF. However, environmental pathogens like Pseudomonas and Mycobacterium (0.5–2%) were not fully eliminated, and Legionella slightly increased in treated water during winter, leading to a mandatory chlorination step post-BF.

The microeukaryotic (Protists) and bacterial communities in the photobioreactor (PHB) biomass (planktonic and biofilms) and DAF were analyzed via microscopy and 18S/16S rRNA metabarcoding over four seasons in Caldes de Montbui. Diverse suspended and biofilm organisms quickly developed in the pilot. The autotrophic community in the PHB consisted mainly of Tetradesmus and related green algae in the planktonic phase, while dense biofilms were dominated by filamentous green algae and diatoms, with seasonal cyanobacteria (Chroococcidiopsis sp., mainly in autumn and spring) also identified. Despite seasonal changes in temperature, insolation, and natural grazers, these communities remained largely stable. Bacterial biofilms in the PHB included abundant denitrifying populations (over 10% of total bacteria), enhancing nitrate removal alongside microalgal growth. The planktonic bacterial population in the PHB was consistently dominated by Proteobacteria, Bacteroidetes, Planctomycetota, and Actinobacteria, with seasonal increases in Bdellovibrionota and Verrucomicrobia during winter-spring. In PHB biofilms, Proteobacteria were dominant year-round, with Cyanobacteria (Chroococcidiopsis) peaking in autumn-spring and Chloroflexi and Verrucomicrobia in summer. The microbial diversity in flocculated biomass from the DAF was highly similar to that of PHB’s planktonic phase, indicating that the Fe₃Cl flocculation in DAF non-selectively harvested the microbial diversity across seasons.

Microbial community in the biofilter (BF) in the period 1 and 2 in the Pilot at Caldes de Montbui: Hydrolytic lignocellulolytic fungi and denitrifying bacteria with active nosZ expression, primarily Denitratisoma sp. (5–8% of relative abundance), contributed to boost heterotrophic denitrification. The microbial community included specialized hydrolytic fungi from waterlogged wood (e.g., Pleurotheciella, Pyrenochaeta Phaeacremonium, Pyrenochaeta, Phialaphora, Cercophora ) and fermenative and denitrifying bacterial populations dominated by the genus Denitratisoma .. 16S/ITS metabarcoding and qPCR of ITS1/16S rRNA showed a natural enrichment of lignocellulolytic microbes on wood and cork beads, with consistent seasonal denitrifier presence (109 nosZ copies/g, 95–100% of total). Gene expression (RTqPCR) of nosZ indicated active denitrifiers in BF beads instead PHB, aligning with peak nitrate removal in the biofilter. Hydrolysis and fermentation by specific fungal and bacterial consortia on wood beads produced volatile fatty acids, promoting denitrification under BF’s saturated conditions.

Microbial monitoring in period 3 in the Pilot at caldes de Montbui : Different groundwater (GW) loads did not impact on prokaryotic diversity in the biofilter biofilm, likely due to the established biofilm's robustness from previous periods (Fig 24). Notably, Denitratisoma remained the predominant genus, consistent with observations in periods 1 and 2, as well as at the Nules site. Functional analysis (FAPROTAX) confirmed enrichment in the biofilter for denitrifying bacteria involved in the complete denitrification pathway, while groundwater was associated with nitrogen fixation, methylotrophy, and photoautotrophy due to surface water input Additionally, significant enrichment of nosZ and aprA genes in the biofilter was confirmed through qPCR, reaching 10⁸ nosZ copies/mg sample across all tested water loading rates.

Seasonal monitoring of microbial communities in Nules pilot: In the Nules pilot plant, 16S/ITS/18S-metabarcoding sequencing revealed that while groundwater (GW) experienced microbial population changes, these did not affect the photobioreactor raceway (RW) at either planktonic or biofilm levels. RW showed enrichment in an unassigned Cyanobacteria genus, predominant across seasons, and DAF also maintained this Cyanobacteria presence.

The BF biofilm in the pilot plan at Nules was enriched over time in denitrifying populations, such as Denitratisoma, which likely established due to the anaerobic and heterotrophic conditions provided by wood pellets. Gene quantification indicated that the microbial population in the biofilter (BF) biofilm remained stable across seasons, except for sulfate-reducing prokaryotes (aprA gene), which decreased by one order of magnitude in autumn (10⁷ aprA copies/g wood). The denitrifying population (nosZ gene) maintained a consistent level across seasons (10⁸ nosZ copies/g wood), mainly enriched in BF biofilm. Analysis of fungal populations via ITS-metabarcoding revealed significant differences at the genus levelin the biofilter: Cladosporium in GW, Alternaria in BFRW, and Purpureocillium in the BF biofilm. While predominant hydrolytic fungi were present at the biofilters in both demo sites (Caldes de Montbui and Nules) , their communities differed in each biofilter.

The autotrophic 18S rRNA communities in the photobioreactor (PBR) were dominated by green algae, particularly Oocystis-like and Chlorella-like species in Nules. After the initial seeding, Tetradesmus became rare, while other Scenedesmaceae flourished. Filamentous green algae were more abundant in biofilm samples than in the planktonic fraction, although less so than in Caldes de Montbui. Green algal residues dominated the algal biomass in the DAF (BDAF-W), while outflows from the biofilter (OUTBF) and DAF (ODAF) were primarily populated by heterotrophic ciliates, notably Paramecium and Metopidae sp.

B7.2: Monitoring microalgae during sludge valorization

Valorization of microalgal biomass: A thickened microalgal biomass (TS 6.1%) from the Caldes DAF, flocculated with FeCl₃, achieved a methanation yield of 66.4 NL CH₄/kg CODt. The microbial composition of this biomass closely matched that of the PHB planktonic biomass, showing consistent microbial recovery in DAF. In contrast, biomass thickened by filtration without FeCl₃ (from the Nules pilot, TS 5.4%) produced 2.5 times more methane, yielding 153.0 NL CH₄/kg CODt. Both biomasses were centrifuged to obtain a clarified liquid containing 83.4 mg/kg phosphate (with flocculant) and 1.4 mg/kg (without). Low-temperature thermal or thermochemical pretreatments (<70ºC) were tested to enhance phosphate recovery, with the best results from biomass without flocculant, achieving 34.6% more phosphate solubilization, though methanation potential dropped by 23% (DL 20). No accumulation of antibiotics or pesticides in the harvested biomass was observed. Only a couple of sulfonamide compounds were detected, and none was found in the April sampling campaign. This suggests that the biomass is safe for reusing as an agricultural fertilizer.

In acidogenic and methanogenic bioreactors fed with harvested microalgae, Methanosarcina consistently dominated the active archaeal population, maintaining over 50% relative abundance, regardless of HRT variations. qPCR analysis indicated that the active methanogens (cDNA) were four orders of magnitude lower than the total population (DNA), with 10³ mcrA transcripts/mL and 10⁷ mcrA gene copies/mL, suggesting potential inhibition of the methanogenic process, likely due to high algal presence hindering anaerobic biodegradation. However, total bacterial 16S rRNA quantification showed no inhibition on fermentative or sulfidogenic activities, with the active bacterial population being one order of magnitude higher than the total (10¹¹ versus 10¹⁰ 16S rRNA transcripts and gene copies/mL). Similarly, aprA transcripts matched aprA gene abundance, indicating a stable active sulphate-reducing prokaryote population.

Microbial analysis of methanogenic activity assays using IRTA’s TM inoculum revealed that microbial populations were more affected by substrate addition (biodegradation of microalgae) than by Fe3Cl concentration. The high organic matter bioavailability in the substrate likely drove changes in microbial diversity in the methanogenic bioreactor inoculum. Additionally, the methanogenic population increased by one order of magnitude (10⁹ mcrA copies/mL) compared to the initial inoculum. Following substrate addition, Methanobacterium accounted for over 50% of the archaeal population, whereas the initial inoculum was dominated by Methanosarcina, indicating a potential shift in methanogenic pathways due to the new substrate (microalgae from DAF).

Monitoring water drinking demo test in a real farm of rabbits: In Spring 2023, a demo drinking water test was conducted on a rabbit farm to compare tap water with treated water from a pilot (DL17).

Microcontaminants in feces: No pesticides or antibiotics were found in either the drinking water or rabbit feces. The treated water showed significantly higher bacterial abundance than tap water, but no notable differences in bacterial content were observed in rabbit feces after 12 and 21 days. The sul1 and intl1 genes were detected in the water, with similar sul1 concentrations in both water sources; however, intl1 was more abundant in treated water. None of the target genes were found in rabbit feces.

Impact of treated water on gut microbiota (rabbit faeces): Before consuming treated water (T1), the rabbits’ gut microbiota was dominated by Firmicutes (70–75%) and Bacteroidota (15–20%). After 21 days (T3), the microbiota shifted to include 60–65% Clostridia, 12% Bacilli, and 4–8% Verrucomicrobia. There were no significant changes in alpha diversity (Chao: 1430–1800, Shannon: 4.7–5.4) due to the water type. A slight depletion of Verrucomicrobia and an increase in Proteobacteria were noted in the treated-water group compared to tap water. Beta diversity and LefSE analysis showed a depletion effect of treated water on Akkermansia and Tyzzerella, while phylotypes related to Lachnospiraceae and NK4B4 increased, indicating a slight impact of treated water on gut microbial diversity at the genus level that warrants further research.

B7.3: Monitoring of cork and wood pellet waste lifecycle

Cork and wood pellet bead materials cycle in the Pilots: To assess the degradation of bead material (a mix of cork and wood pellets) after two years in biofilters, various analyses were conducted and compared to the initial materials. These analyses included moisture content, apparent density, dry density in helium, particle size distribution, total polyphenols (measured by the Folin-Ciocalteu index), and porosity and surface area using gas adsorption techniques.

After two years, the bead material exhibited a true density similar to wood pellets (1.33–1.42 g/cm³), but a higher specific surface area (1.30–2.41 m²/g) and total pore volume (1.80–3.30 mm³/g), which were 30 and 25 times higher than initial wood pellets and six to eight times higher than initial cork. Total polyphenols in the bead material were significantly depleted (81–96%), indicating biotransformation likely due to microbial degradation of more digestible organic fractions in both materials. Despite this, heterotrophic denitrification rates remained stable after two years, suggesting continuous biodegradation of lignocellulosic materials, which increases the specific surface area and promotes the colonization of new microbial populations for hydrolysis and denitrification. The minimal decrease in density suggests the bead material retains complex carbon structures for ongoing denitrification in the pilots.

B.8. Transferability and replicability plan and business plan (All partners)

Action B8.1: Economic validation

Comprehensive data collection, calculations and estimations have been made for the assessment of the economic viability of LIFE SPOT process at different scales. This includes the determination of LIFE SPOT technology construction and operational costs and potential benefits in comparison to conventional RO treatment. Results have shown that LIFE SPOT process offers important economic savings in terms of energy consumption and avoids brines generation and management. All partners have participated in this task.

Action B8.2: Exploitation and Business plan

A detailed Business plan has been developed for the commercialization of LIFE SPOT technology and associated services, after the project end. This has included, on the one hand, a marketing and commercialization plan with market research of potential target scenarios and audience, competing technologies (mainly RO) and value positioning regarding LIFE SPOT environmental benefits (water efficiency, lower energy consumption and absence of brines generation) and reasonable investment return period. Then, a market structure identification has been made and represented in a Canvas Model for easy identification of the different agents and stakeholders that may be involved in LIFE SPOT technology commercialization. On the other hand, a sales, distribution and communication strategy has been defined, where the constitution of a new company (SPOT Solutions LTD) has been proposed for the commercialization of LIFE SPOT technology with collaboration with the LIFE SPOT consortium. As an early approach, internal organization, legal structure and human resources for the new company have been defined with a progressive company growth during the first five years after the project end.

Up to 5 plant sizes have been proposed for LIFE SPOT commercialization to meet the requirements of different target scenarios from single-family rural houses to small municipalities, including small houses groups, farms or rural schools. Then an economical and financial study has been performed to analyze initial financial requirements, necessary supplies, other direct costs, indirect costs, personnel costs, expected revenues, cash flow and risk assessment for a 5-year commercialization projection from the project end. This has confirmed the economic sustainability of the LIFE SPOT commercialization business and foresees a positive rentability after 5 years of the commercialization begin.

Action B8.3: Transferability and replicability plan

A Replication and Transfer plan (R&TP) has been proposed to explore the potential implementation of LIFE SPOT technology in different scenarios and applications. First of all, a geographical analysis focused in Spain but not excluding other European regions has allowed to identify different zones with nitrates and micropollutant contamination, highlighting the potential of 3 main regions for the R&TP execution: Castelló province, Aragon region and Catalonia (Fig. 13 A). There, several affected and sensible wells and groundwater bodies in different municipalities have been identified, allowing the delimitation of sub-zones with higher concentration of potential scenarios for the LIFE SPOT replication. An advisory board with experts and key stakeholders have been constituted which has allowed a deeper exploration of the situation and potential cases in Castellón and Aragon. Then, general replication and transfer projections definition (coherently with the Action B8.2. Business Plan) have been proposed attending the basic data collected from the different potential sites in Castellón, Aragon and Catalonia to be executed during the first 5 years after the project end. This includes 13 replications for drinking water production from polluted groundwater and 2 transfers for nitrates removal in WWTP effluents and RO brines treatment. For this projection, several business cases based on real and hypothetical scenarios have been defined such as a farm, a school, a research centre, and a small municipality.

|

|

|

|

|

(A) |

(B) |

(C) |

Figure 13. Geographical analysis of nitrates pollution in groundwater in Spain (A), rural school replication case (B), and WWTP for transfer case (C)